Exolith Lab

At the University of Central Florida’s Exolith Lab, I worked on developing a proof-of-concept system for solar sintering of lunar regolith: a process that uses concentrated sunlight to fuse simulated lunar soil into solid blocks. This technique addresses one of the biggest challenges for off-Earth construction: how to build infrastructure on the Moon without transporting massive amounts of material from Earth.

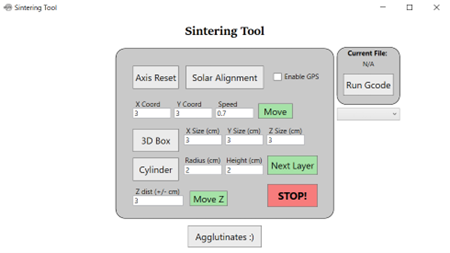

Our team designed and built a semi-automated sintering stand featuring a large Fresnel lens that concentrates sunlight into a high-temperature focal point. Mounted on a steel and 80/20 aluminum extrusion frame, the system integrates three-axis motion control, limit switches for safety, and a Raspberry Pi with computer-vision solar tracking to keep the lens aligned with the Sun throughout the day.

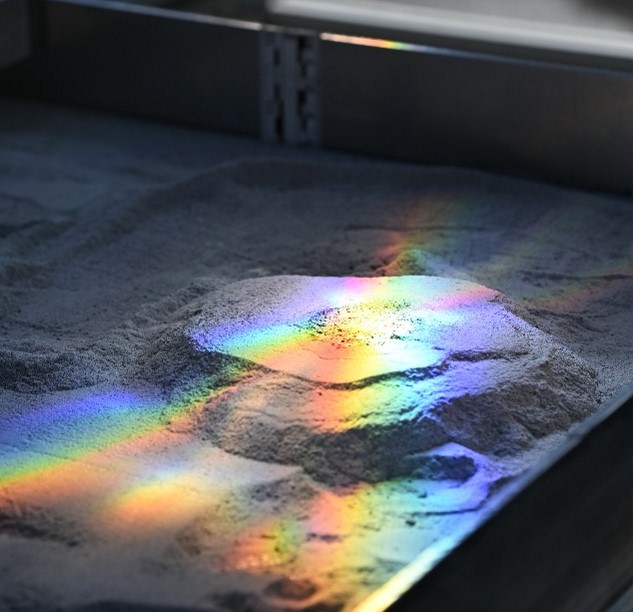

The process begins with a mixture of LHS-1 lunar highlands simulant and aluminum powder (75:25 by weight), which is spread into thin layers. The concentrated solar beam is then guided across the surface in programmed paths, locally melting and bonding the material. Layer by layer, this approach demonstrates how lunar regolith could be turned into functional bricks or structural elements using only sunlight as the energy source.

We faced several challenges while developing the solar sintering system. Our first issue was figuring out how to rotate the Fresnel lens for elevation; we narrowed our design options to a belt-and-pulley system or using Kevlar rope with a DC motor, ultimately choosing the latter for cost efficiency. The bottom motor controlling azimuth was originally the same DC motor used for the X and Y axes and mounted on a 3D-printed part, but it struggled with slack during rotation and the print weakened over time. This was largely due to earlier cost-saving design choices and the steep learning curve of the previous undergraduate team, so we upgraded the system with a gearbox and wheel hub for more reliable performance. The motors also overheated when exposed to direct sunlight, which we resolved by insulating them with thermal bubble wrap. Beyond these major fixes, we encountered many smaller mechanical and coding issues that we worked through iteratively, each one improving the system’s overall reliability. Putting all those issues into one article might make this article a pain to read.

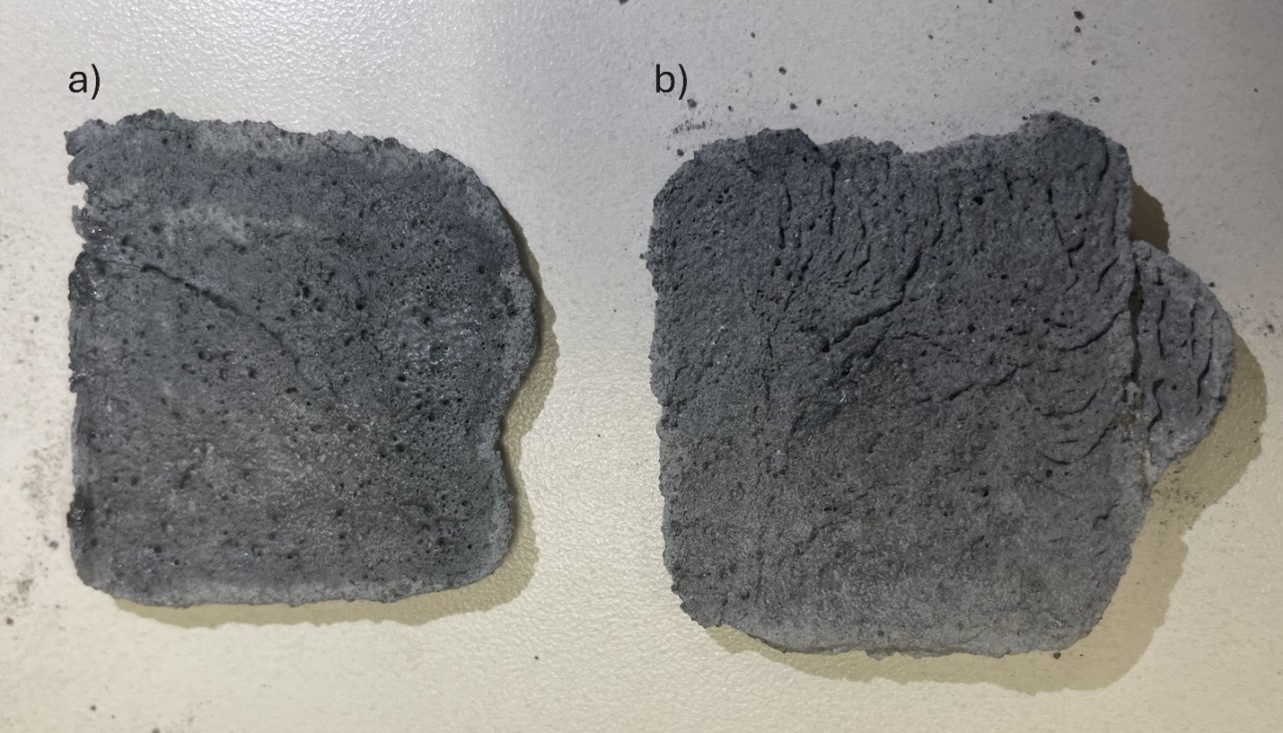

Testing confirmed that the system can reliably produce fused regions and small multi-layer samples. Darker, glassy areas in the sintered tracks indicated strong bonding, while compaction techniques significantly improved part integrity. Weather presented limitations; clouds or any haze reduced efficiency, but under clear skies the stand consistently achieved fusion at high temperatures using no external power beyond sunlight.

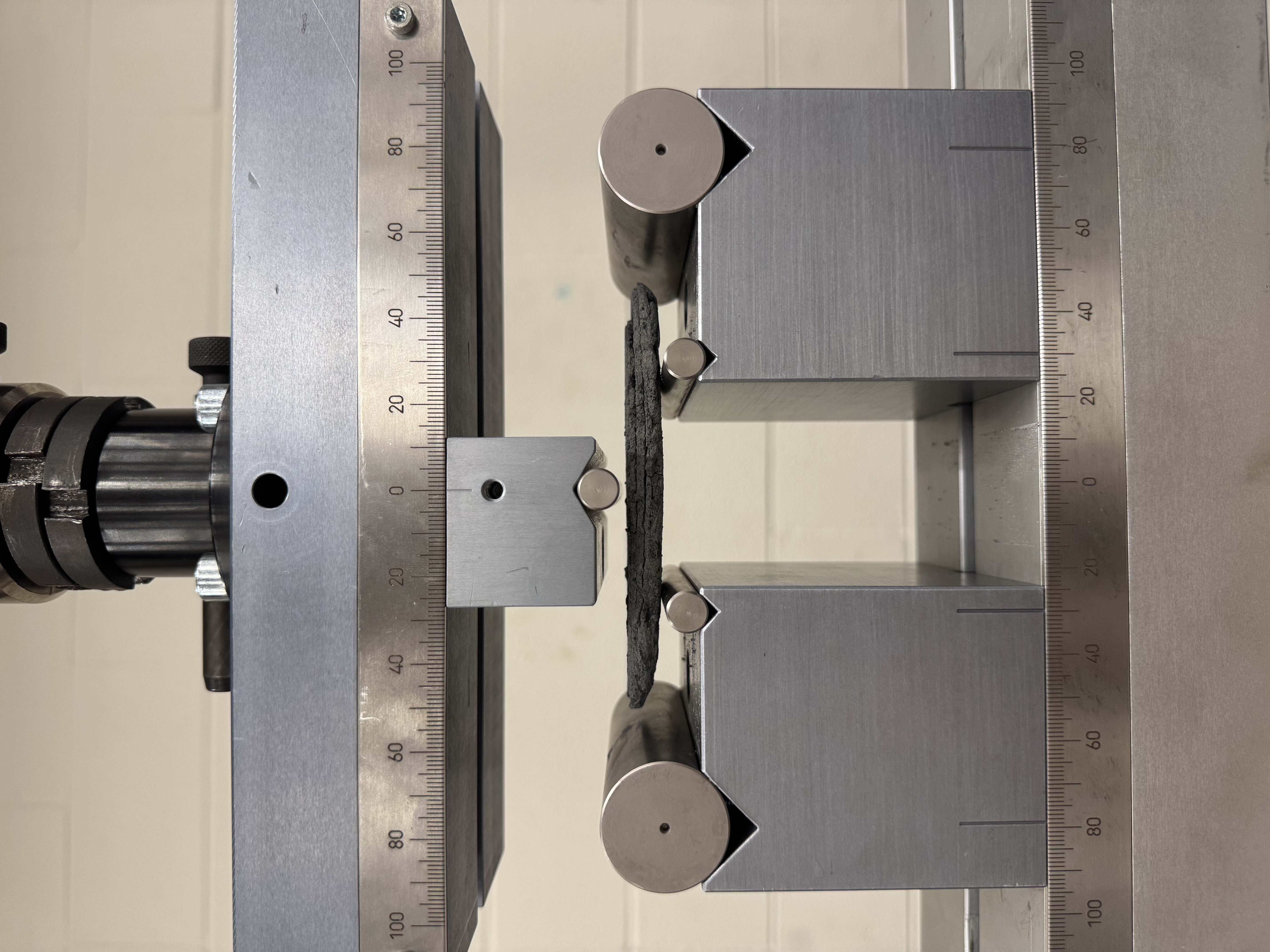

While waiting for clear weather conditions to continue solar sintering experiments, we performed flexural bend and compression tests on premature samples in an effort to extract preliminary mechanical data. Even though the samples were inconsistently fused, these tests helped us assess the degree of bonding achieved and provided early insight into potential material strength.

The results highlighted significant variability: some samples fractured almost immediately during handling, while others withstood noticeable stress before failure. Interestingly, compression tests performed better than flexural bend tests. This indicated that the premature samples could carry load in compression, but their internal porosity and lack of uniform bonding made them brittle under bending or tensile stresses.

This work highlights the potential of in-situ resource utilization (ISRU) for future lunar missions. By leveraging local materials and abundant solar energy, solar sintering could reduce the cost of transporting construction supplies from Earth and enable the creation of landing pads, radiation shielding, and habitat components directly on the Moon.

Our next steps include automating powder deposition, refining the tracking system, and testing under vacuum conditions to better simulate the lunar environment. This project represents an early step toward sustainable human presence beyond Earth—showing that with ingenuity, today’s laboratory demonstrations can become tomorrow’s lunar infrastructure.

A paper on this has been approved to be presented at AIAA Scitech 2026 in Orlando, Florida.